- 首頁

- 問與答

問與答

-

Formation of Carbon Buildup

Carbon buildup occurs because fuel is composed of hydrocarbons. In an ideal state, an internal combustion engine would achieve perfect combustion, leaving behind only water and carbon dioxide. However, this is practically impossible to achieve in reality. Consequently, under conditions of incomplete combustion, a viscous, gummy substance forms on the fuel injectors and valves—this is what we call "carbon buildup.

-

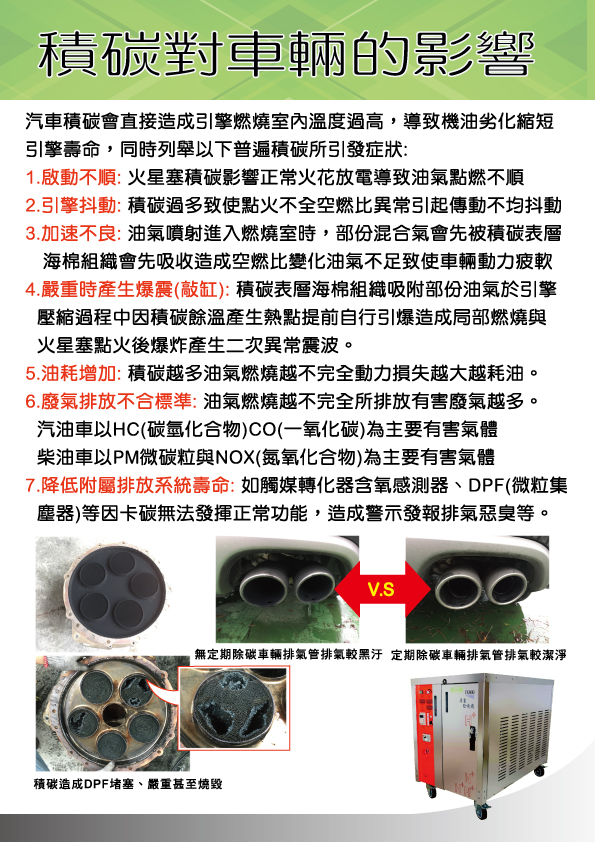

Effects of Carbon Buildup on Vehicles

Whether it is a heavy-duty vehicle, a compact car, or a gasoline or diesel engine, any fuel-powered machinery utilizing an "internal combustion engine" will inevitably produce "carbon buildup" over time, leading to the following issues:

1.Increased fuel consumption

2.Engine vibration (shaking)

3.Poor acceleration

4.Engine knocking

5.Abnormal exhaust emissions

6.Reduced lifespan of exhaust system components

-

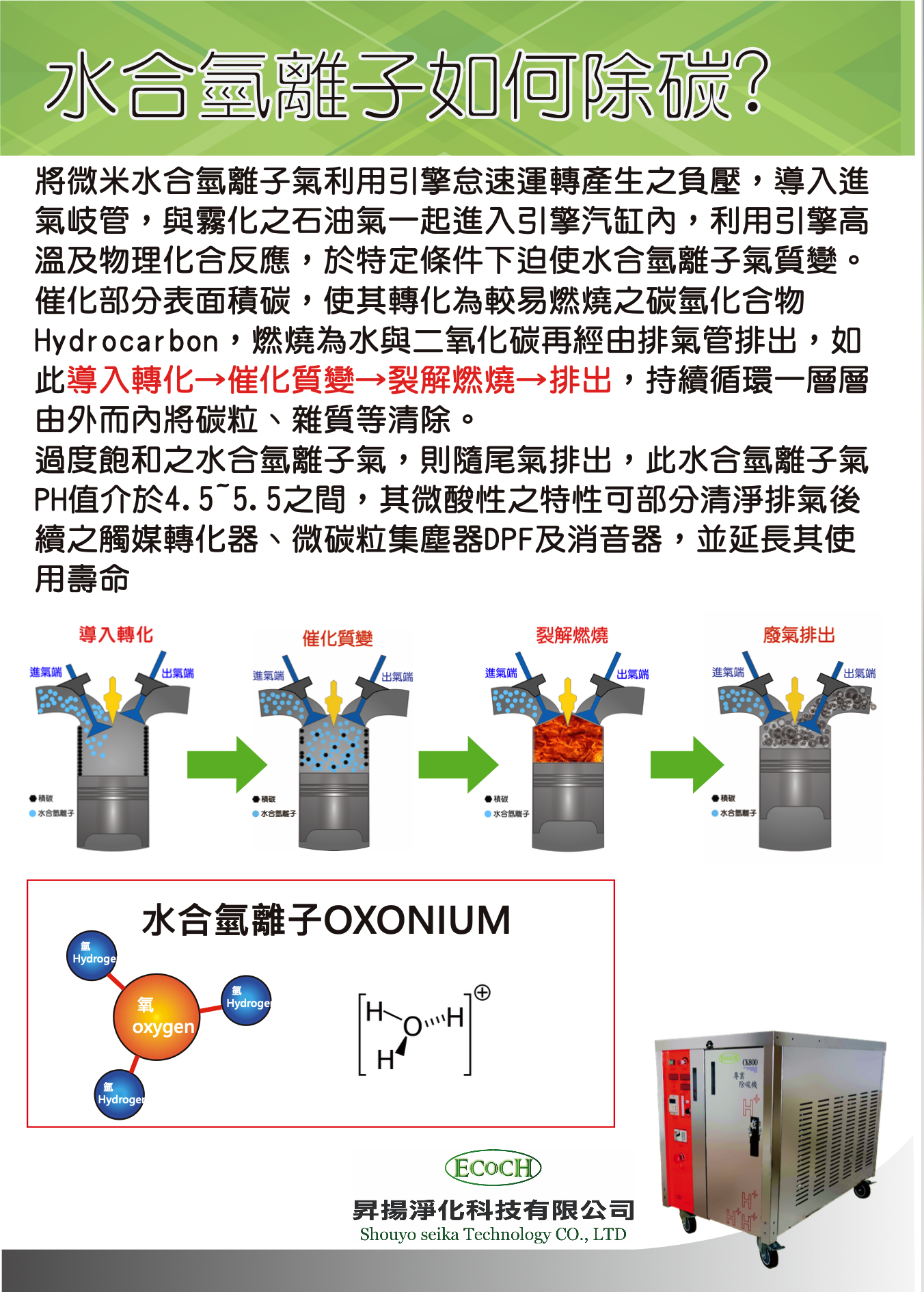

How Hydronium Ions Remove Carbon Build-up

Micron-sized hydronium ion gas is introduced into the intake manifold using the vacuum pressure generated by the engine during idling. It enters the engine cylinders along with the atomized fuel gas. Utilizing the engine's high temperature and physico-chemical reactions, the hydronium ion gas undergoes a qualitative change under specific conditions. This catalyzes surface carbon deposits, converting them into more easily combustible hydrocarbons.

Hydrocarbons are burned and converted into water and carbon dioxide, which are then expelled through the exhaust pipe. Through this continuous cycle of introduction, conversion, catalytic transformation, thermal cracking, and exhaust, carbon particles and impurities are cleared layer by layer from the outside in.

-

Benefits of Carbon Removal

1. Smooth coasting immediately upon shifting into gear

2. Improved fuel combustion efficiency

3. Avoidance of engine disassembly and major overhauls

4. Extended engine service life

5. Prevention of Diesel Particulate Filter (DPF) clogging and burnout